Illumination Light Source Module for Checking large glass substrates

In this time, let me show you a lighting module equipment for inspecting flaw before shipping large glass substrates.

We have a lot of experience which developed and manufactured beam projectors like Sayview, Ecoview etc in the past.

The core of this work was adjusting uniformity.

The total area is 15% uniformity of light illuminating an area of 2.2m * 2.1m.

When receiving an offer from the company, I initially think it would be not difficult because I have many experience dealing with lenses and front surface mirror.

However, I got to know how difficult it to make 85% uniformity in this extent area while conducting basic research prior to production.

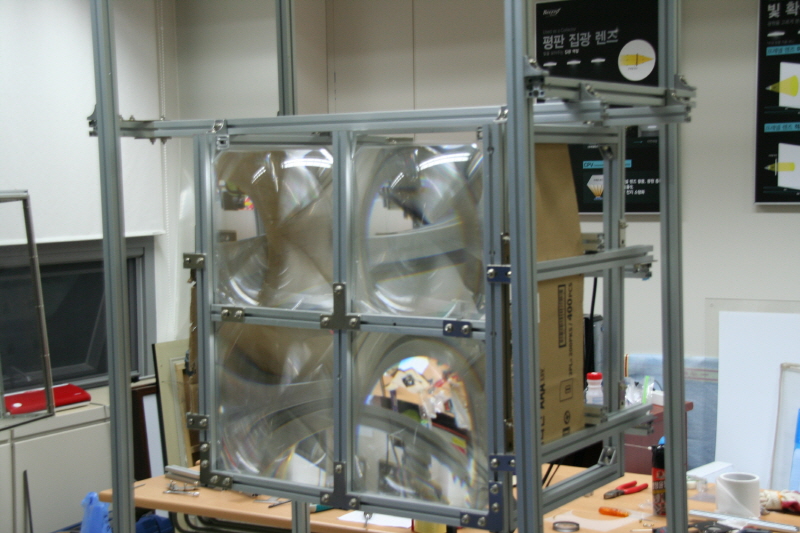

< Manufacturing the same enclosures for exact test 6787>

< The first prototype 6720>

The first prototype was produced using Fresnel lenses. I used lense to solve a problem that field was tilted about 15 degrees.

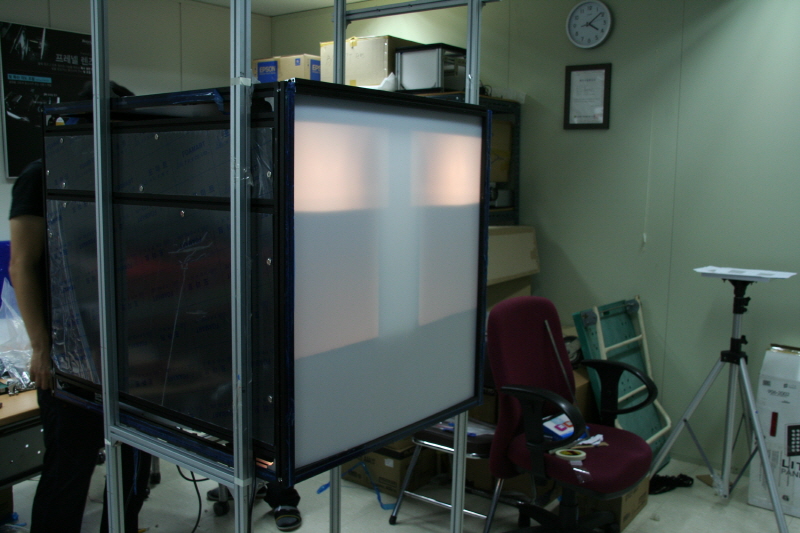

< The second prototype 6865 >

I used a diffuser to increase uniformity.

It was a diffuser which is about 800 * 600mm.

I used two diffusers, transmissivity of first one is 85% and another is 90%, which developed by us.

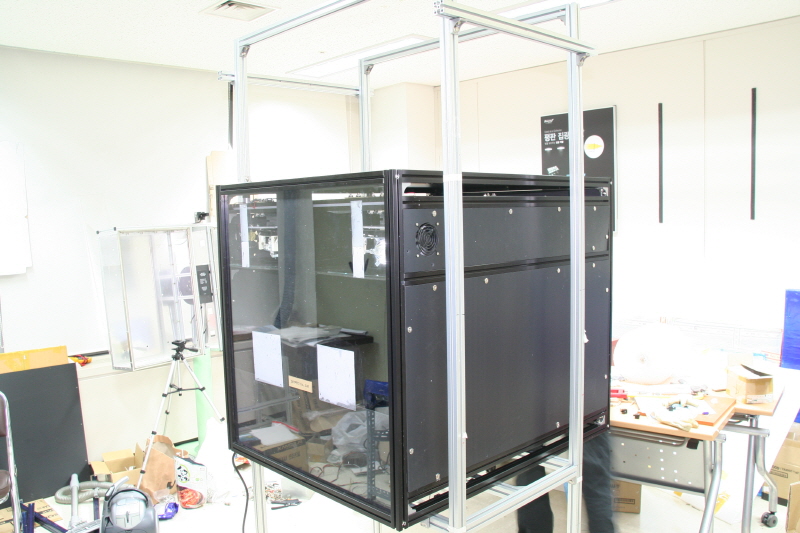

< Final Product 6895>

< A photo before shipping the product 6898 >

It is composed of reflectors, optical mirrors, and three diffusers using four light source.

It nearly took a month to produce it. It was not easy, but worthwhile.

----------

Question for optical products development

Myung Joong Kim, DIYPRO

070-7605-1652