LED type HIGH BAY DOWNLIGHT

November 23, 2015

Product : LED type HIGH BAY DOWNLIGHT

Applied optic : : Multi-array Lens (Fly eye Lens)

The product we have finished development this time is LED type High-bay-Light which is usually used in the factory and hall. It is a development of optical lens of the improvement of existing product, not as a new product. For light sources, 260 pieces of LED ship were used, applying multiple array with 1:1 corresponding between light and lens.

The existing lens used was with beam angle 20 degrees, not good in the optic design and quality, which resulted in an unsatisfactory luminous efficiency. The client who requested DIYPRO development of lens wanted us to design a new lens having light distribution angle 60 degrees with improved luminous efficiency.

◈ ED lighting fixtures

LED chips were arrayed as shown in the above picture.

Different from what is seen in the picture, Distance between the LED chips were not uniform, so that there was difficulty to set light source and lens.

◈ Existing lens(beam angle 20 degrees)

The existing lens as a Bi-convex lens has empty spaces between lenses, and this caused bad luminous efficiency and beam leak phenomenon.

◈ Lens developed by DIYPRO( beam angle 60 degrees)

In the newly developed lens, it was designed hexagon shape to enhance the efficiency of lens and to eliminate the leak of light,

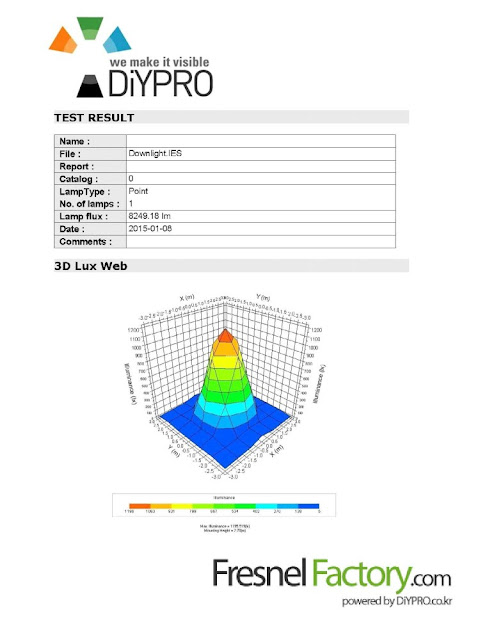

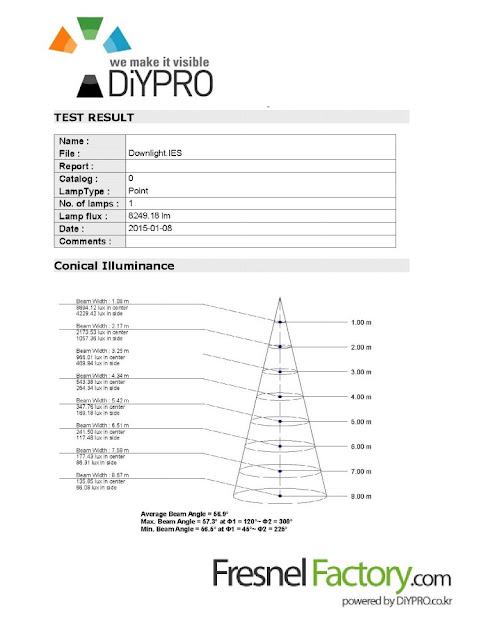

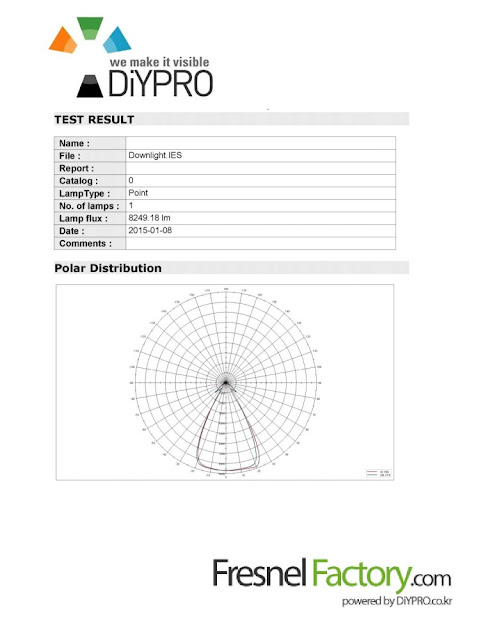

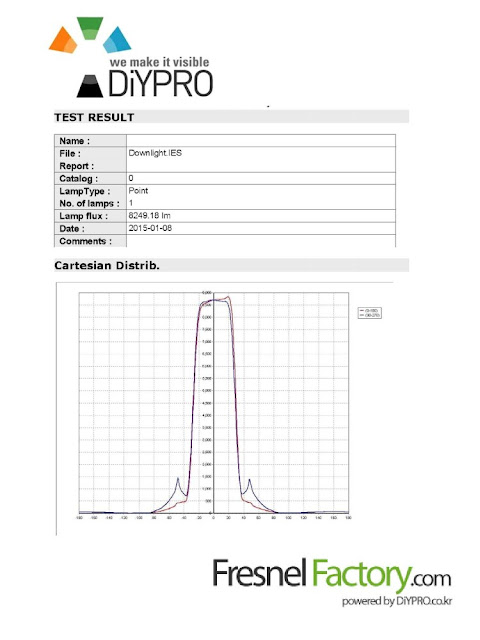

◈ Measurement result of light distribution applying lens developed by DIYPRO

1. Average Beam Angle : 56.9˚

2. Lamp Flux : 8249.18lm

3. Lumen Per Watt : 110lm/W

Beam angle of new lens was developed with 60 degrees but 5% difference arose due to the structure of lighting fixture. The luminous efficiency of new DIYPRO lens was improved twice compared with the existing lens. Its main reason of improvement in the luminous efficiency is attributed to wider beam angle, quality of lens surface and the level of optic design capability.

◈ Comparison of quality between the existing lens and the new lens

Above picture; left is existing lens and right is newly developed lens from DIYPRO. In the picture, you can see the differences in the transparency of lens that bottom part is mirrored through and quality difference. In the next picture, I will compare the lens surface with the bigger pictures.

When we film the close-up of the lens, wave shaped fringes on the surface of lens and foreign material in the lens made during the mold injection. It is very important to form a even surface for the accurate refraction of light. The wave like fringes is the main cause of quality deterioration. Above lens used a low quality PMMA, not suitable for optical purpose lower the transparency of lens noticeably.

For the outstanding quality of lens developed by DIYPRO, we control the surface quality of lens in nanometer and use high quality optical use PMMA with transmittivity 94%. And we designed individual lenses in hexagon shape to improve brightness efficiency of lens

DIYPRO provides one-stop solution from Fresnel lens designing to mass production as a specialized optical industry dealing with Fresnel lens and total reflection mirror, and imports and produces various total reflection mirrors with high reflexibility 92~98% without distortion.

DIYPRO provides one-stop solution from Fresnel lens designing to mass production as a specialized optical industry dealing with Fresnel lens and total reflection mirror, and imports and produces various total reflection mirrors with high reflexibility 92~98% without distortion.

Tel. 070-7605-0693

Fax. 031-259-7500